Titanium hexagonal flange nut - Grade 2 - M4 - DIN6923 / ISO4161

Technical specifications:

TITANIUM GRADE: Grade 2 | T40 | DIN 3.7035

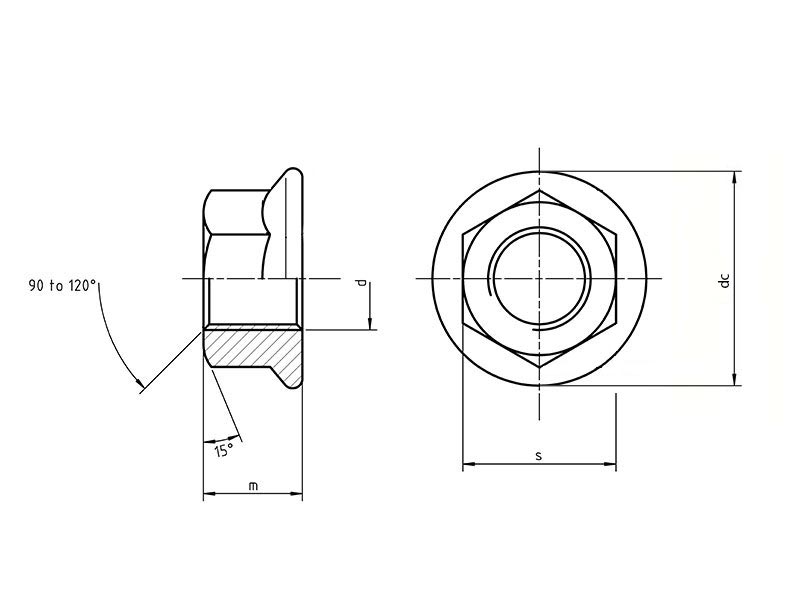

STANDARD: DIN 6923 / ISO 4161

Nut diameter (d): M4

Base diameter (dc): ~9.10 to 10.0mm

Distance between 2 plates: ~7.00 mm

Height (m): ~ 4.30 to 4.50 mm

Weight: ~ 0.76 grams

A titanium flanged hexagonal nut is a common basic element in mechanics/DIY, intended for the assembly of moving parts.

The advantages of the titanium flange nut compared to a classic titanium nut type "H / DIN 934" are:

- The forces are distributed over a larger surface area, thanks to the base, which reduces the pressure on the plates.

- The base offers the possibility of covering oversized titanium bolt/screw holes.

- Adding a titanium washer is not necessary.

The distance between two faces corresponds to the size of the wrench; which can be flat, ratcheting, socket, etc.

For this titanium nut with an M4 flange, the wrench size is 7.

The titanium flange nut can be used with:

Note:

- DIN934 hexagonal titanium nut.

- low titanium nut DIN439B.

- titanium nylstop nut / self-locking DIN 985 , with a nylon ring.

- titanium nut with nylstop/intractable flange (DIN6926) , with a nylon ring.

- titanium wing nut / butterfly nut (DIN315).

- blind titanium nut (DIN1587 – on order).

- custom-made titanium nut (made to order).

If you wish, you can add a material certificate 3.1 for this product.

It is valid for this nut only ( see bottom of page ) or click on the following link

DID YOU KNOW?

Titanium is:

- 43% lighter than steel

- High mechanical resistance (grade 5)

- Low coefficient of thermal expansion and heat transfer

- 100% stainless steel!! Much better than stainless steel!

Questions and Answers:

The main difference is that grade 2 is pure titanium, while grade 5 is a titanium alloy (titanium + aluminum + vanadium). Each grade meets a specific need: Grade 2 titanium has an excellent ratio of corrosion resistance to mechanical strength and weight. Contrary to popular belief, the mechanical strength of grade 2 titanium is lower than that of steel but remains much higher than aluminum. It offers good cold formability and excellent weldability. Grade 2 is primarily used in saline, chlorinated, and acidic environments. It is found in the chemical and petrochemical industries, jewelry/watchmaking (for parts not requiring high mechanical stress), medical applications, etc. Grade 5 titanium has three times the mechanical strength of grade 2. It is also higher than that of steel and stainless steel… all with a weight that is 43% lower than these materials. In addition to its excellent strength-to-weight ratio, grade 5 titanium offers good weldability. Grade 5 titanium is used in the aerospace, naval, military, oil and chemical (reactors, pumps), and motorsports industries, among others. "For motorsports or if you have high mechanical stresses, you absolutely need grade 5 titanium." These two grades of titanium are the most commonly offered, but others exist. More information about titanium can be found on our dedicated page.

None! Each country/organization uses its own standard/designation. Therefore: Grade 2 = T40 = DIN 3.7035

Yes, we can manufacture custom titanium nuts. Simply provide us with as much information as possible (dimensions, whether it's based on an existing standard, etc.), ideally a dimensioned drawing. A

minimum order of 50 to 100 pieces, depending on the type of part, is required to begin production. The manufacturing lead time is approximately 4 to 7 weeks, depending on the time of year.

Regarding pricing, a personalized quote will be provided as soon as possible.

Please feel free to contact us.

To get a quick quote for titanium parts, you have two options: If you've found the titanium product(s) you're looking for on our website, simply add the desired quantity to your cart and validate your cart and the form (on the cart page) by clicking the "Request a Quote" button. This is the simplest and fastest method. You can also use the contact form on the dedicated page, and we will do our best to respond as soon as possible. This method is recommended for custom-made titanium screws, products not listed in our catalog, or for large quantities.

All our titanium products are sold individually… unless otherwise indicated as a “lot,” “set,” etc. Please note: photos are for illustrative purposes only. Differences may exist between the photo and the actual item. Therefore, we encourage you to carefully read the description and/or contact us.

In 99% of cases, an order placed before noon is shipped the same day*… but this depends on several factors: If your order is validated before 2:00 PM (Paris time), payment must have been received and validated, and your information has been correctly entered in your customer account. *Please note that this information has no contractual value… but we are very responsive ;o)

We sell and ship our titanium products virtually worldwide. Only a few countries are excluded. Please see the list of excluded countries in the " Shipping "

Yes, if it's mentioned on the product page. It's an additional charge (see product details at the bottom of the page or here).

The certificate is valid for one type of product: same diameter/thickness and same grade.

If you order extra material certificates, we will notify you as soon as possible, and if you pay by credit card or PayPal, we will charge you the correct amount immediately. If you pay by bank transfer, we will include a discount voucher for your next order.

Unfortunately not. All our titanium products are in their "original/natural" color, which is gray. The gray can be more or less matte or glossy depending on the titanium grade, the annealing process, any heat treatment, etc.

The information on this site may contain technical inaccuracies or typographical errors and may be changed at any time without notice.

Photos are for illustrative purposes only.