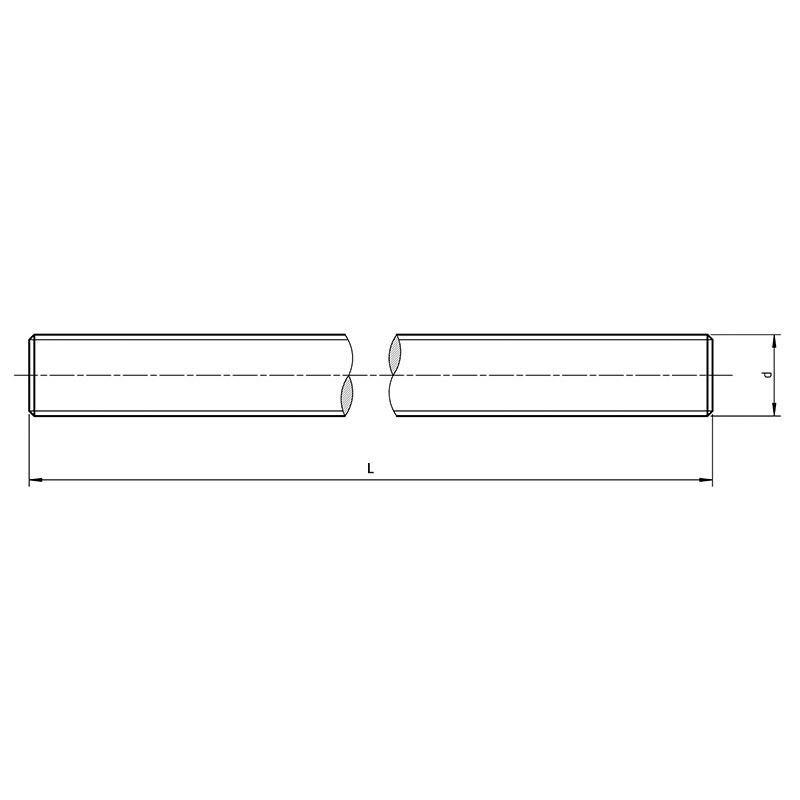

Titanium threaded rod Grade 5 / TA6V - DIN975 - M6

Technical specifications:

TITANIUM GRADE: Grade 5 | TA6V | DIN3.7035

STANDARD: DIN 975

Head diameter (d): M6

Screw length (L): 500 & 1000mm

Thread length: Full thread

No screw: 1.0

Thread type: rolled

Weight: ≈ NA grams per 1000mm

Titanium threaded rods are much more than just fasteners. They represent the perfect combination of strength, lightness, and corrosion resistance. Featuring a long cylindrical shank, they offer exceptional threading, whether along their entire length or only at the ends, also known as studs. Compared to traditional headless screws, these titanium rods stand out for their superior strength and increased durability.

Advantages of titanium threaded rods

- Lightweight robustness : Titanium offers impressive strength while being remarkably light, ideal for applications requiring both strength and lightness.

- Corrosion resistance : Unlike traditional metals, such as steel or stainless steel, titanium is naturally corrosion resistant, ensuring unparalleled longevity even in aggressive environments.

- Extreme versatility : Titanium threaded rods can be cut to the desired length, offering exceptional adaptability and versatility to meet a variety of applications.

- Lightweight robustness : Titanium offers impressive strength while being remarkably light, ideal for applications requiring both strength and lightness.

Applications of titanium threaded rods

The unique advantages of titanium threaded rods make them a preferred choice in many industries, such as:

- Building and construction trades

- Manufacturing industry

- Automobile

- Plumbing

- Shipyards

- Aeronautics

Discover the superior quality and unrivaled performance of titanium threaded rods at www.titanium-services.eu, your partner for reliable and durable fixings.

You can combine this titanium threaded rod with:

Note:

It is valid for this type of titanium screw in this diameter and grade, regardless of length ( see bottom of page ) or click on the following link for more information.

DID YOU KNOW?

Titanium is:

- 43% lighter than steel

- High mechanical resistance (in Grade 5/TA6V)

- Low coefficient of thermal expansion and heat transfer

- 100% stainless steel!! Much better than stainless steel!

- High resistance to acids, chlorine, in saline environments... (grade 2 / T40)

Questions and Answers:

The main difference is that grade 2 is pure titanium while grade 5 is a titanium alloy (titanium + aluminum + vanadium).

Each grade meets a specific need: Grade 2 titanium offers an excellent balance of corrosion resistance, mechanical strength, and weight. Contrary to popular belief, the mechanical strength of Grade 2 titanium is lower than that of steel but remains significantly higher than that of aluminum. It offers good cold formability and excellent weldability. Grade 2 is primarily used in saline, chlorinated, and acidic environments. It is found in the chemical and petrochemical industries, jewelry and watchmaking (for parts not requiring high mechanical stress), medical applications, and more.

Grade 5 titanium has three times the mechanical strength of grade 2. It is also superior to that of steel and stainless steel… all while weighing 43% less than these materials. In addition to this exceptional strength-to-weight ratio, grade 5 offers excellent weldability. Grade 5 titanium is used in the aerospace, naval, military, oil and chemical (reactors, pumps), and motorsports industries, among others. “For competition or if you have high mechanical stresses, you absolutely need grade 5 titanium.”

These two shades of titanium are the most commonly offered, but others exist.

More information about titanium can be found on our dedicated page .

None! Each country/organization/standard uses its own name.

So: Grade 5 = TA6V = Ti-6Al-4V = DIN 3.7164

Grade 5 titanium, TA6V, Ti-6Al-4V, and DIN 3.7164 are actually different designations for the same titanium alloy . Here is a detailed explanation:

Ti-6Al-4V : This is the chemical designation of the alloy, indicating that it contains approximately 6% aluminum (Al) and 4% vanadium (V), the remainder being titanium (Ti).

Grade 5 : According to the American ASTM (American Society for Testing and Materials) standards, Ti-6Al-4V titanium is classified as Grade 5. This is the most commonly used grade due to its excellent mechanical properties and corrosion resistance.

TA6V : This is the French designation for the same alloy. "TA" stands for "Aerospace Titanium", and "6V" refers to the 6% aluminum and 4% vanadium (the "V" being for vanadium in French notation).

DIN 3.7164 : This is the German standard (DIN) for this specific titanium alloy.

In summary, there is no material difference between these designations . They all represent the same titanium alloy Ti-6Al-4V, but are used in different contexts or industrial standards (American, French, German).

Yes, we can produce custom-made titanium screws.

Just give us as much information as possible (dimensions, whether it's based on an existing standard, etc.), ideally a dimensioned plan.

You need a minimum of 100 pieces (or even 200 for screws smaller than M3), depending on the type of part, to start production.

The manufacturing time is approximately 4 to 7 weeks depending on the time of year.

Regarding pricing, a personalized quote will be provided to you as soon as possible.

Feel free to contact us .

For the manufacture of titanium screws, a distinction must be made between the threading and the manufacture of the titanium screw head and/or its recess.

For the threading:

- It is rolled for titanium screws with diameters from M1 to and below M20.

- It is machined for diameters M20 and above.

For screw heads and sockets:

- For all Grade 5 titanium screws = Direct turning, cold stamping for hollow heads.

- For Grade 2 titanium screws, up to M8 diameter, the same technique applies as for Grade 5 titanium screws.

- Grade 2 titanium screws, with a diameter greater than M8, have heads that are first hot-forged and then cold-hammered to create hollow-recess heads.

To obtain a quick quote for titanium parts , you have two options:

- Once you've found the titanium product(s) you were looking for on our website, simply add the desired quantity to your cart and confirm your order by clicking the "Request a Quote" button on the cart page.

You can also leave a comment on the same cart page if you wish.

This is the easiest and fastest way to proceed. - You can use the contact form on the dedicated page, and we will do our best to reply as soon as possible.

This method is recommended for custom-made titanium screws, products not listed in our catalog, or for large quantities.

All our titanium products are sold individually… unless otherwise indicated as “lot”, “Set”, …

Reminder: the photos are for illustrative purposes only. There may be differences between the photo and the actual item.

That is why we invite you to read the description carefully and/or contact us.

In 99% of cases, an order placed before 11:00 am is shipped the same day*… but this depends on several factors:

- If your order is validated before 11:00 (Paris time), payment must have been received and validated.

- If your information has been correctly entered on your customer account.

*Please note that this information has no contractual value… but we are very responsive ;o)

We sell and ship our titanium products virtually everywhere in the world. Only a few countries are excluded.

Please see the list of prohibited countries in the " Delivery "

Yes, if it's mentioned on the product page.

It's an additional charge (see the product page at the bottom).

The certificate is valid for one type of product : same diameter/thickness and same grade.

If you order extra material certificates, we will notify you as soon as possible, and if you pay by credit card or PayPal, we will debit the correct amount immediately.

If you pay by bank transfer, we will include a discount voucher for your next order.

Unfortunately not.

All our titanium products are in their "original / natural" color, i.e., grey.

The grey color can be more or less matte or glossy depending on the grade of titanium, the annealing of the titanium, any heat treatment…